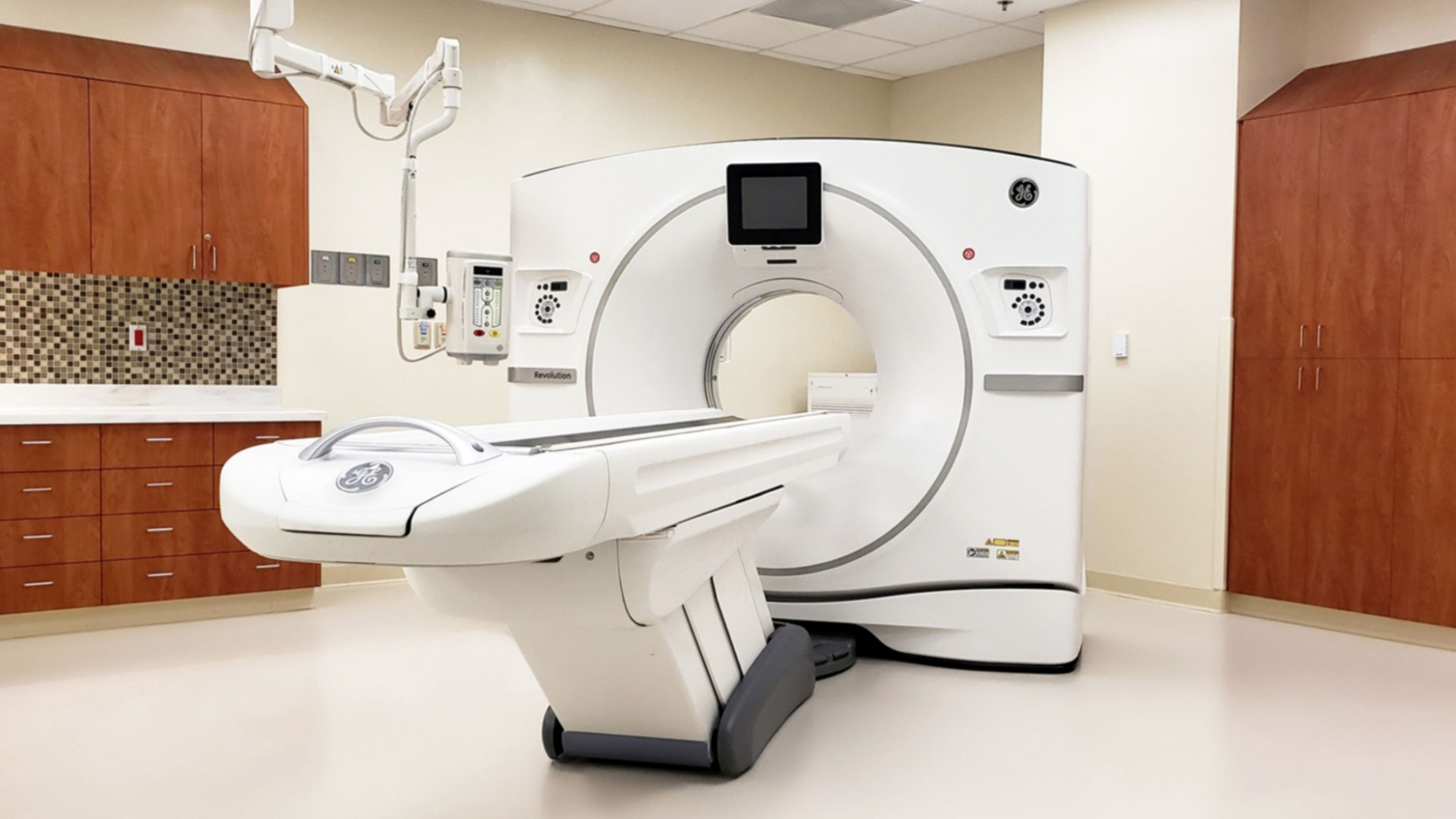

Healthcare

For nearly 15 years, Calray Electric has delivered electrical solutions in active hospital environments, including as one of the top electrical contractors at VA San Diego. Our teams bring specialized expertise and deep code knowledge to every project, whether it’s ground-up construction or upgrades to existing infrastructure. We handle complex projects such as surgery suites, life-safety and mission-critical systems, and are certified to install and commission Uninterrupted Power Supply (UPS) units. Throughout every project, we prioritize minimizing disruptions to hospital operations while delivering reliable, high-quality results.

Healthcare Projects

VA Prosthetics Lab Relocate & Expand – Phases 1 and 2, VA La Jolla:

This project was a multi-phase project that included the temporary closure of half of the existing Prosthetics lab, as well as tying in new construction to existing spaces. This project was successfully completed in the beginning of 2022.

The scope of work included selective demo in an active hospital, installation of new power and lighting with an energy efficient lighting control system, running feeders for new 200-amp panels, running raceway for a AC split unit on roof, installation of a new 600v 60 amp service disconnect, provided power to all the VAVs, and coordination for all low voltage systems, including access control, fire alarm, data, nurse call, CCTV, and DDC systems.

This project required multiple phases, as well as off hours construction shifts to reduce impact and disturbance to patient care. The surrounding areas of this project remained fully operational during construction. The area initially was contaminated with Asbestos through demolition. This required extra diligence in keeping our PPE and infectious control procedures in place.

Med Gas Alarm, VA La Jolla:

Calray worked directly for the VA Healthcare System and successfully completed the installation of conduit, specialty wire and Amico gas monitor panel; including 3rd party testing of the alarm panel.

VA San Diego Replace OR LIM Isolation Monitors and Transfer Switches, VA La Jolla:

Calray successfully completed a multiple phase project in an active hospital that included providing emergency power systems to the Operating rooms and other critical care areas of the building including installation of new switchboards, ATS’, feeders, and generator controls. This project required critical coordination between many departments within the care facility as well as the resident engineer to ensure the transition between old and new was seamless and had as little impact on patient care as possible. As part of the project scope we provided and installed two new ATS’ at the penthouse and basement; provided multiple switchboards and panelboards; provided all necessary wiring and conduit between these ATSs, switchboards, and panels; provided normal and emergency feeds for ATS 14 and ATS 15. Coordinated outages on EDB1, SWBD ‘C’, and SWBD ‘E’ to provide circuit breakers and terminate feeders in those panels with Resident Engineer. Replacement of CEM1. Coordinated extended outages with Resident Engineer.

Expand Community Living Center Phase, VA Loma Linda:

The second phase of the Community Living Center Expansion added a one-story 13,000 square foot, ground up, slab on grade construction project to the existing hospital. Calray Electric, Inc worked closely with the electrical engineer and VA facilities personnel to tie in new power, emergency power and an ATS system to ensure the building would maintain power at all times.

Calray Electric provided the power, energy efficient LED lighting, lighting controls, site lighting and gear in a timely manner that ensured this project was completed ahead of schedule.

Single Patient Conversion, POD A, VA La Jolla:

Calray Electric provided electrical support to convert previously unused space into patient care with 8 beds and a nurse’s station. This work was completed inside of an active hospital and Calray Electric took steps to reduce any impact to patients and VA personnel. This project included providing hospital grade lighting, power and receptacles to headwall units, power of automated shades and a lighting control system.

Expand Electrophysiology Lab, VA La Jolla:

This project resided in a multi-story, occupied hospital. As a result our crews worked during multiple shifts to reduce impact to patient care, while working in containment where ACM was present. Our crew maintained the proper certifications and wore the required PPE and additional Hazmat safety suits and respirators.

Calray Electric, Inc. provided electrical support to renovate the 4th Floor West Radiology Department Electrophysiology Lab. The scope of work included selective demolition in an active hospital environment; relocation of GE medical equipment; provided and installed new medical grade, LED lighting and controls, as well as cove lighting to create a comfortable patient experience; provided access control, fire alarm, data, nurse call; coordinated with medical equipment vendors for GE, Stryker and Skytron to deliver a complete and operable system.

VA Patient Services Phases 2 & 3, VA La Jolla

This project also resided in a multi-story, occupied hospital. As a result our crews worked during multiple shifts to reduce impact to patient care, where ACM was present. This was a multi-phase project that included the temporary closure of corridors, as well as tying new construction into existing spaces.

Calray Electric, Inc. provided electrical support to renovate the 1st Floor Volunteer and Patient Services Department. The scope of work included selective demolition in an active hospital environment; provided and installed new power and lighting, as well as energy efficient Exergy lighting control system, provided conduit, back boxes and coordination for all low voltage systems, including access control, fire alarm, data, nurse call, CCTV and DDC system.

This project required multiple phases, as well as off hours construction shifts to reduce impact to patient care. The surrounding areas of this project remained fully operational during construction. The area was contaminated with Asbestos through demolition. This required extra diligence in keeping our infectious control procedures in place. This work was performed at a medical facility and was a federal project. This required the additional payroll and other reporting to be provided in a timely manner to ensure compliance Federal regulations.

Other notable projects include:

- Hot and Cold Water Risers, VA La Jolla

- Boiler #3, VA Long Beach

- Site Perimeter Upgrade, VA Long Beach

- Symbia S Room, VA La Jolla

- Atrium Roof HVAC, VA La Jolla

- Parking Structure security upgrades, VA La Jolla

- Building 1 Water Damage Remediation, VA La Jolla

- Elevator Modernization, VA La Jolla

Industrial Tenant Improvements

Our team brings extensive experience managing complex industrial tenant improvements on a large scale. Projects often involve demolition of existing infrastructure and strict adherence to design guidelines and critical schedules. We approach every project with precision and efficiency, ensuring it meets client expectations and project milestones.

Industrial Tenant Improvements Projects

RM14-0136 Energy Renovation B207 at NAB San Diego:

Retrofitted 400+ existing luminaires, with dimmable ballasts and new lamps. This included installation of lighting controls. Also assisted in the upgrade of the mechanical system by providing new GRC conduit, disconnects and feeders.

Energy Renovations B335 B1481 B618 at NASNI San Diego:

Completed all required demo and safe-off, installation of disconnects, raceways and connections for new HVAC units, extended existing power to new chiller equipment, removal and replacement of interior lighting fixtures and lighting controls, installation of grounding as needed for new lighting fixtures.

B-A33 Replace HVAC Bard Units Rm 4226 NAVFAC FEAD Point Loma:

Provided new panel boards, transformers, NEMA 4X enclosures, and the complete conduit and feeder wires to support new air handling equipment.

Federal Design-Build

Calray Electric partners with General Contractors to provide design-build electrical services for federal projects. We deliver ROM estimates during bid preparation to help secure work and collaborate closely with design teams to maintain budgets, ensure code compliance, and coordinate with other MEP trades and engineers. During construction, Calray remains an integral team member, helping projects run smoothly and achieve successful completion.

Federal Design Build Projects

PE1321M Repair MEU Building 210824, MCB Camp Pendleton, CA:

Design-build project that Calray provided design assistance, including a full tenant improvement of the lighting, lighting controls, fire alarm and other low voltage systems, electrical distribution to support mechanical system improvements, and wiring re-design to accommodate new FF&E.

D/B Naval Surface Warfare Center, Seal Beach, Detachment Corona; Norco B509 Area Distribution Node (ADN) Facility:

The new 4,000 sq. ft. modernized building incorporated advanced technologies in heating, ventilation and air conditioning using hot-aisle containment “PODS,” power regulated by microprocessor-based power panels, and an advanced battery backup system, generator tie-ins, and a clean agent fire suppression system.

Interior Repairs to C3F Tactical Training Building-58, Naval Base Point Loma, San Diego, CA:

This was a Design-Build project to repair C3F B58 at Third Fleet Campus at Naval Base Point Loma to meet UFC 1-200-02 High Performance and Sustainable Building Requirements and solved all existing problems at this facility to accomplish a useful and appropriate facility for military training of operation and war-fighting. The electrical scope of work included replacing and adding LED lighting, providing electrical connections for new HVAC system and equipment, providing the backbone pipe for low voltage systems including DDC and Fire Alarm, upgrading the electrical distribution to support all new equipment, lighting, and functions at the upgraded facility.

RM515-14 Design Build Restore Finishes Bldg. 500, Naval Base Point Loma, CA:

This was a Design-Build project to repair Building 500 at Naval Base Point Loma to meet UFC 1-200-02 High Performance and Sustainable Building Requirements and solved all existing problems at this facility to accomplish a useful and appropriate facility for the occupants. The electrical scope of work included replacing and adding LED lighting, providing new electrical for built out office spaces as well as electrical connections for new HVAC system and equipment, providing the backbone pipe for low voltage systems including DDC and Fire Alarm, upgrading the electrical distribution to support all new equipment, lighting, and functions at the upgraded facility.

Nanosatellite Lab, Bldg. 89, NIWC PAC, Topside, Naval Base Point Loma, San Diego, CA:

Renovation of an existing pre-engineered building to a clean secure high-tech research space. The electrical work included demolishing of existing electrical system, and complete re-installation of electrical system including Service Entrance Wiring and Equipment, Distribution and Lighting Panel boards, Conduits, Feeder and Branch Circuits, Motor Control Equipment, Lighting and Branch Wiring, Communications, Security and Alarm Systems, Emergency Lighting and Power, and Grounding. All devices and piping were installed in a surface mounted manner.

Munitions Maintenance and Inspection Facility at Edwards AFB, CA: In Progress:

Construction of a 7,000 square foot, single story, multi-bay Munitions Maintenance Facility at Edwards AFB. Calray Electric provided the complete electrical system from the ground up including site underground; installation of all electrical equipment including transformer, switchboards, and panelboards; LED lighting and Lighting Control system; explosion proof Class 1, Division 1 high bay lighting and devices for hazardous areas; and installation of a 400hz system.

Renovate Elrod Exchange Bldg. 2499, Marine Corps Air Station Miramar, San Diego, CA:

This was a design/build project to renovate the Elrod Exchange, Building 2499, at MCAS Miramar. Work included a new food bar, a new dry-cleaning space, new cabinets and checking counters, new flooring and ceilings, new finishes, and re-configuring the sprinkler system. MEP work included replacing the existing walk-in and reach-in refrigerators with new refrigerators, adding a new HVAC system, replacing existing electrical panels, and new LED lighting. This project was coordinated with Marine Corps Community Services (MCCS).

CPEN BEQ 53451 Camp Pendleton, CA:

BEQ 53451 was a design build project with 64 units at 53 Area, Horno, Marine Corps Base, Camp Pendleton for the continued use of the 1st Marine Regiment billeting. BEQ 53451 is a 29,442 square foot, two story concrete masonry unit (CMU) structure built in 1975. The existing building was in poor condition and required work to bring it up to current Building Code and life safety standards. The building received upgrades to plumbing systems and fixtures, electrical systems, windows and doors, locks, fan coil units and general architectural finishes.

NASNI B472 Fastems Flexible Manufacturing System, Naval Air Station North Island (NASNI), Coronado, CA:

Calray Electric scope of work included new electrical service to the newest and most high-tech CNC machine shop on Naval Base Coronado. This project included providing power to six DMG Mori CNC machines as well a Fastems conveyor and lifting system that full automates the process for the client Fleet Readiness Center.

Fire Life Safety (FLS) Upgrades, SoCAL TRACON Facility, San Diego, CA:

Federal Aviation Administration (FAA ): Calray Electric provided electrical support at the critical SoCal FAA Tracon facility in Miramar, CA. This included major upgrades to the fire and life safety systems of critical importance to air travel safety. Calray Electric scope of work included new electrical service to the fire pump controller; demolition, and replacement of three existing Central Battery Systems; illuminated exit signs with battery backups; and shunt trips for return fans. This also included the installation of ASSD, FACP, FATC panels, Nitrogen generator, compressor, RELP, Fire alarm conduit & Megger testing with test reports.

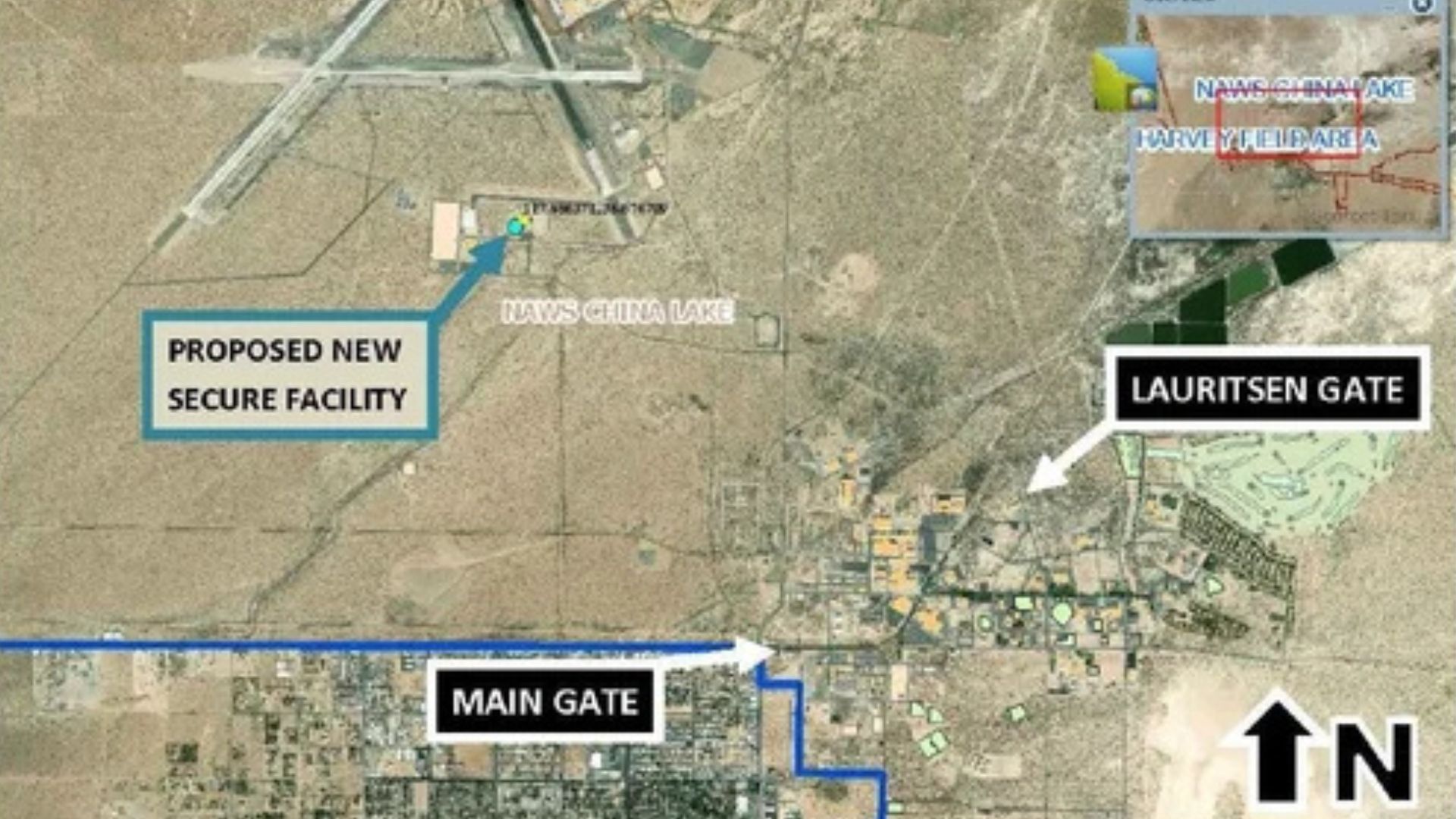

Secure Spaces

Calray Electric has the expertise to work in Sensitive Compartmented Information Facilities (SCIFs) and ICD 705. We excel in the design and implementation of the secure spaces standards. Our teams seamlessly handle working in environments without access to their electronics and are adept at RF shielding, dielectric breaks, and other requirements of secured spaces.

Secure Spaces Project

Construct Secure Facility F-18 IPT, NAWS China Lake, CA This was a ground up construction of an 8,000 sq ft ICD 705 facility.

Point Loma Arial Lab Modernization at Naval Base Point Loma, CA

This project was a renovation to a 6,700 sq ft dry lab space to support collaborative, data-driven research and innovation in science and engineering. The design included flexible lab areas for multiple classified projects, collaborative workspaces, and upgraded power, HVAC, and communication systems. Calray provided lighting, lighting controls, power, including panelboards, disconnects and associated feeders, and conduit raceway for security systems.

Federal Bid-Build

We provide trusted electrical services for a wide range of federal Bid-Build projects. Our clients include the Department of Veterans Affairs, U.S. Army Corps of Engineers, Department of the Navy, U.S. Air Force, and the Federal Aviation Administration. We combine technical expertise and deep federal experience to meet strict project requirements with reliability and precision.

Federal Bid Build Projects

Repair Earthquake Damage at Building 15988 Radiographic Inspection Facility (RIF), Naval Air Weapons Station (NAWS) China Lake:

After July 2019 earthquakes at the NAWS China Lake; Calray assisted in bringing this building back to pre-earthquake operational levels and efficiency. The included the replacement of all underground conduits and cabling within the new slab repair, as well as restoration of all distribution and related power. Replaced high bay fixtures at the top of the RIF via 80-foot knuckle boom lift.

Repair Earthquake Damage at Building 16160 Trident II Horizontal Test Facility (HTF), Naval Air Weapons Station (NAWS) China Lake, Ridgecrest, CA:

After July 2019 earthquakes at the NAWS China Lake; Calray assisted in bringing this building back to pre-earthquake operational levels and efficiency. This included the complete inspection and replacement of 20 existing high bay lights, restoration of all distribution and related power.

Repairs to Airfield Fire Station, Building 20009, China Lake, Ridgecrest, CA: Built in 1945, the Airfield Fire Station is critical to operations of the North Range at Naval Weapons Station, China Lake. Calray assisted in the modernization of this building, including new LED lighting, fire alarm system, and new HVAC throughout.

19001 Fort Rosecrans Cemetery:

This project created one new slab on grade prefabricated metal storage building, one open covered storage shelter and one vehicle wash station in an efficient maintenance yard with defined and secure areas for national cemetery staff, equipment and vehicles and contract maintenance equipment and vehicles. Calray also provided Class 1, Siv 1 wiring for a fueling station.

PHIBCOR-505 Replace Fire Protection

Building 505 (Kelly Hall) at NAB was built in 1989. It is a 10-Story High Rise Bachelor Officer’s Quarters approximately 130,000 SF or approximately 12,800 SF per floor. Calray provided a new fire alarm/mass notification system and removed the exiting conventional fire alarm system. We also provided a new diesel standby generator and connections to a new fire pump and associated equipment.

Renovate B52 and B11 Server room NBPL:

This project consisted of renovating and improving training spaces and server rooms in two (2) buildings for Fleet Anti-Submarine Warfare, Harbor Drive, Naval Base Point Loma. In building 11, construction includes dividing 2,260 SF room 333A into four smaller rooms. Improvements were made to electrical, mechanical, and fire protection systems. In building 52, work includes replacing the aging and inadequate HVAC system to support the installation of new server racks. Calray Installed new LED lighting, Upgraded the UPS back up system and installed new power distribution units to serve the new in-row cooling.

USACE Omaha ACU-5 Fueling Repairs, Camp Pendleton:

Calray performed fueling system repairs at Assault Craft Unit 5 (ACU 5) Camp Pendleton, CA. ACU-5 is the US Navy’s Pacific operating unit for the Landing Craft Air Cushion (LCAC). This project upgraded recirculation piping, repaired filter separators, repaired trench drains, removed mechanical equipment, removed fuel piping, demolished, and removed a fuel storage tank, and repaired pavement at load/offload points

Services & Special Projects

Calray Electric offers flexible solutions for both new and existing clients, handling a variety of electrical upgrades and special projects. Our work includes smaller-scale electrical system improvements, lighting upgrades for energy efficiency, and electrical support for mechanical systems. From interior to exterior improvements, we provide dependable solutions that keep projects moving forward on schedule.

Services & Special Projects

Del Mar Fair/22nd DAA Storm Treatment Plant:

Calray Electric provided storm drain water quality improvements for the Del Mar Fairgrounds. The work included reconstruction and lining of existing lakes, construction of a wetland within one lake, installation of new storm drain systems within existing Fairground facility areas, installation of storm drain best management practices (BMP) devices, an underground detention area, and construction of a small water treatment plant.

The work of this project was phased in coordination with the 22nd District Agricultural Association and Del Mar Thoroughbred Club, in order to allow for the San Diego County Fair, Del Mar Racing Season, and all other event operations to occur without impacts from construction.

Al labor, material and equipment for the Electrical de-energize and safe off, temp power generator, de-watering temp power and conductors, ACS raceway wiring and terminations, Div 26 complete including sawcut, breakout, trench, backfill and compact, Div 22 raceway, wiring, Div 23 raceway work scope, all in accordance with SWPPP plan, contract drawings, specifications, and industry standards for your trade, including, but not limited to work referenced in the following specification sections